Knowing how to spot signs of wear and tear and when parts need to be serviced or replaced will positively impact the life of your respirator.

Back to Articles & Resources View all Using Your Respirator content

There are many factors that will determine the life of your respirator, whether it’s your application, frequency of use, or the byproducts in your immediate environment. Knowing how to spot signs of wear and tear and when parts need to be serviced or replaced will positively impact on the life of your respirator. By doing this, you can ensure you and your team are always getting the right protection with your respirator.

Headtops

Your headtop has several components that need to be regularly inspected in order to ensure you’re always being protected. One key area is the seals on your respirator. These are there to ensure you’re protected from your environment by preventing any contaminants from making their way into your respiratory system. The seal can become damaged from abrasive materials, sparks and paint making. Over time this compromises the strength of the seal, degrading the material and making it ineffective. A general rule we recommend is to replace visor seals every 3 months and cape seals every 3-6 months. This, however, is completely dependent on the user and this time will vary based on frequency of use, along with harshness of materials.

The capes/hoods have a varying life expectancy which is dependent on their application and their frequency of use. Our painting range should be replaced every 1-3 weeks, abrasive blasting every 2-4 weeks, and welding/grinding every 9-12 months.

Our headtops have been designed specifically for the environments they are used in. Because of this, factors such as UV exposure, abrasive materials, hazardous overhead objects, and exposure to chemicals/paints will affect the life of them. For the applications that require a hard hat certification, we recommend replacing them within 5 years to ensure they are still providing you with the protection you need. It’s always important complete regular inspections of the respirator for any signs of wear of damage and replace as and when appropriate.

It’s very important to regularly check the inside of your headtop as this is in constant contact with your head and any sweat can cause to the material to deteriorate. Internal touchpoints need to be cleaned weekly and any material components are machine washable and should be washed for hygiene purposes. We recommend that the hygiene kits are replaced every 6 months.

PAPR, SAR, & Accessories

Filters in our PAPR units are extremely important to monitor as these are stopping the contaminants in your environment from making their way into your respiratory system. These must be checked daily and require replacement often because of their frequent use. As best practice the pre-filter should be replaced each day or at least twice a week for applications that do not require constant use of the PAPR. HE filters need to be replaced every 2-4 weeks (subject to frequency of use and application). Those that are in constant use and filtering more hazardous contaminants will require replacement sooner. If a spark resister is used this should be checked daily for any signs of wear and tear.

With supplied air, the Radex Airline Filter needs to be replaced every 3 months or 400 operating hours (whichever comes first). This needs to be changed regardless of application and frequency of use because the filter is activated and if used beyond this time frame this will no longer perform to the same level.

Breathing tubes for both PAPR and SARs require replacement every 6-12 months. These needs to be checked daily for any damage along the hose and the seals where the product attaches to the head tops or air supply.

Our climate control devices need to be cleaned daily and filters replaced every 1-2 months.

The gas sensors in the GX4 have a shelf life of 2 years from the time of manufacture. After 2 years, the GX4 displays a message indicating that the sensor has expired. We recommend checking the sensors at least monthly for calibration.

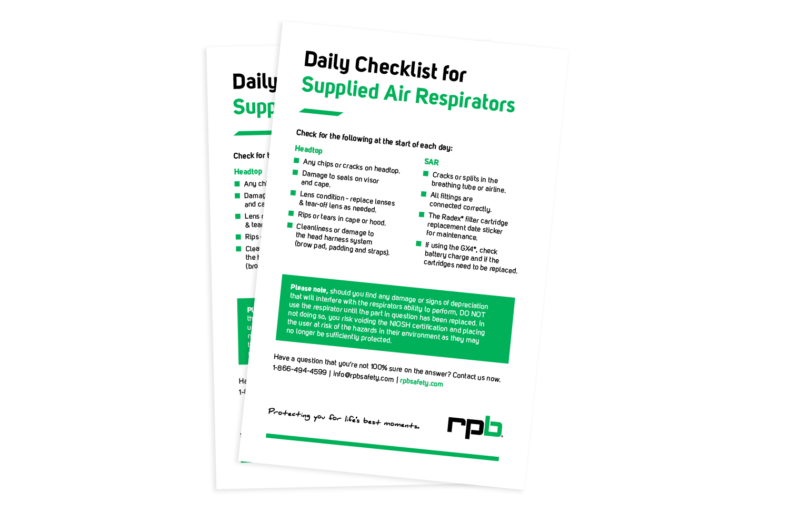

By following these general guidelines, you’re ensuring you’ll always have fully functional respirators protecting you and your team. Please note these are guidelines and as mentioned the frequency of replacement parts may vary dependent on application and frequency of use. To keep on top of this we recommend using our daily checklist. For further information please visit our website or contact our team.